How long have you been working with wood?

I have been working with wood since I was a little kid. My grandfather and grandmother had engineering degrees, and both of them were extremely skilled in all aspects of construction. Both could frame a wall and sheath a roof, but my grandmother did the plumbing and my grandfather did the electrical!

They rebuilt the family camp when I was about 5 years old. One of my earliest memories is sitting on the rough-cut floor deck with a bunch of my cousins (all between the ages of 5-10) and our job was straightening nails that had been pulled out of the original camp. My father built our home when I was in the fourth grade, and I used to help him after school and on weekends. Both my father and grandparents used a lot of local timber throughout the entire build process, so there were always scraps around for me to play with and construct small projects.

As I got older, I would help my grandfather work on various projects not only on our camp, but many of the surrounding camps as well. What stuck with me the most was how the camps were originally built with real solid Maine wood, and how long it lasted. During college I renovated part of a historic mansion into a student lounge for my senior project. As I tore into the grandiose original structure, I was struck again by how everything was built using real solid material and how long it had held up to Maine’s harsh coastal climate.

After college and a bit of travelling I made my way back to Maine and started focusing on construction and renovations. I started using all the techniques and similar materials that I had learned and worked with in past projects. The familiarity of working with real wood felt very natural and it helped me be more creative with uses and design in my work.

What is it about wood that you love and appreciate?

Working closely with my grandfather, father, and many family relatives, I got the opportunity to work on many different structures. We would be under a camp built in the early 1900’s, replacing rotted sills and some of these beams had already had a previous life – you could tell because of random mortise joints that were cut into the beams and some still had the peg and tenon intact. That really gave me an appreciation for wood and its durability.

The great thing about wood is that every part of it can be used. If you have a 12” wide piece of 3/4 stock you can rip it down to fill in a 7 5/8″ wide gap in your subfloor, and that left over piece can then later be ripped down to 3 1/2″ door trim and the left over 3/4″ strip can be used for inside corner trim. Any cuts and left over scraps can then be bagged up and used as kindling for the wood stove. As building products move to more composites and chemically engineered materials, the by-products and waste are not easily disposed of and most end up in landfills. There is a noticeable difference at the end of the work day between cutting vinyl siding and pine clapboard siding.

Favorite wood project?

One of the most memorable wood projects I have been a part of was restoring the alewives’ chute on the Damariscotta Mills fish ladder.

There is a fish ladder in Damariscotta Mills that allows alewives (a small herring species) to travel back from the ocean each spring and head to their spawning grounds in Damariscotta Lake. The ladder was originally built in the 1800’s and consists of roughly 90 pools built out of loose place stones. Over the many decades the fish numbers have fluctuated, but in recent years the community has maintained the pools to keep the fish stock plentiful in order to use the alewives as bait for lobstering. Each spring millions of fish return, and because of the endless work and maintenance that the community puts into this project, once enough fish have made it up the ladder the alewives can then be harvested and sold to lobstermen as bait and the proceeds help maintain the ladder.

The way the fish are harvested is there are two mechanical scoops that lift the fish out of the water at the head of the ladder, and lift them into a wooden chute that sends the fish down to waiting crates and eager lobstermen. This process hasn’t changed or been improved much over the years. The chute consists of raised sections of pine troughs laid inside each other with enough slope to keep the fish and water flowing. The construction is pretty simple: two sides and a bottom with a couple of cross braces.

The old chute had been there as long as anyone could remember, and was weathered with moss and lichen growing on it, rotted, leaking, held together with nails, screws, wire, anything on hand! To match what was there, we got 12″ wide by 1′ thick rough cut pine boards from a local mill and replaced the chute section-by-section, leaving the boards untreated. What made being a part of this project memorable was the fact that we could help keep something going that had been around for so long and was still being used. The remains of the previous chute were set aside and I was able to salvage enough of the grey, weathered wood to make some beautiful frames (lichen still intact) that were auctioned off at a fundraising event.

Best wood/wood project story?

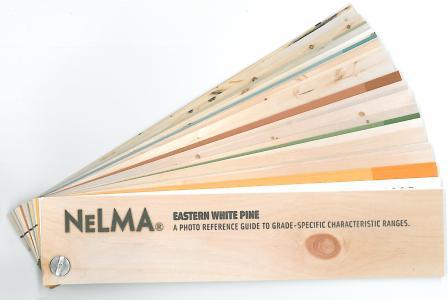

It’s really hard to choose a best/favorite wood project story. Through Maine Cabin Masters we have been fortunate to be able to work on over 80 cabins across the great state of Maine. Each cabin is special and has a unique story that we get to be a part of. We have seen all types of construction, used a ridiculous amount of eastern white pine, and visited many different sizes and styles of lumber mills. We have filmed in many angles and with many lenses the entire life (from seedlings to finished lumber) of Maine’s and the Northeast’s prolific forests.

Where do you think wood fits into today’s home improvement/building industry? Wood will always be an integral part of the home building industry. The durability, versatility, and accessibility of real solid wood is unrivaled. New materials and products will always keep showing up that look and simulate the beauty of wood (and they do have their uses), but why buy a sheet of something that looks like wood grain when you can have the real thing.