As the world grapples with the environmental devastation plastic production has wrought, attempting to clean up a gyre of plastic trash in the Pacific Ocean that’s twice the size of Texas and filter dangerous micro plastics out of our drinking water, some innovators are working on alternative materials with similar properties.

Plastic was initially envisioned as an environmental boon based on the misconception that cutting down trees for wood products is always a bad thing. (It’s not.) But its creators and champions failed to consider the end of the product’s lifecycle as well as the amount of energy and resources it requires to manufacture.

Not only are plastic recycling rates far too low, plastic can only be recycled so many times before it degrades into tiny particles that are difficult to see and clean up but harmful to the health of humans and wildlife. Since it doesn’t biodegrade naturally, it could take thousands of years for the planet to recover. Meanwhile, new technology like 3D printing still finds plastic to be an alluring material thanks to its flexibility and strength.

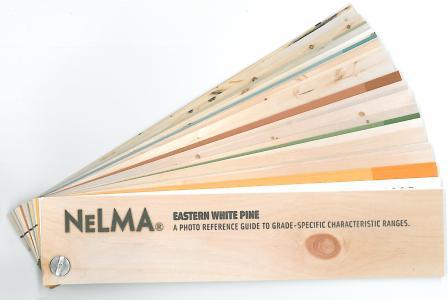

Renewable, sustainable and biodegradable, wood is still a strong competitor for plastic, and now it can play a role in the 3D printing revolution as well. Canadian bioplastic company Advanced BioCarbon 3D (ABC3D) has developed wood-based bioplastic materials for engineering applications. It’s made of waste wood cut down during wood collection by forestry companies. Resin is extracted from the waste wood and the leftover wood is turned into a polymer. The resin is added back to the plastic to give it heat resistant and moisture resistant properties.

“If we have extreme weather events happening all the time, it’s going to interrupt every part of society,” says ABC3D’s environmental scientist Kim Klassen. “So, climate change, above all other environmental concerns, is important and that is what this company addresses through product development, through sustainable bioplastics made from renewable resources.”

“People often think of bioplastics as single-use with low-value functionality, but our products are incredibly high-functioning with exceptionally high heat resistance while being lightweight … As an example, our goal is to be able to 3D print something like a piston for your car from this material – there’s such high heat resistance, and it’s also very strong,” says Darrel Fry, CEO of ABC3D.