The source of your wood products matters. If you want to feel great about your finished project, taking pride in the materials you choose will be a major element in your success. Why go with lumber that comes from environmentally questionable or downright illegal sources when you could have exemplary quality, expertise, service and sustainability all at once? We like to check in with “green” sources of Eastern White Pine now and then, and today we’re featuring Michigan-based Biewer Lumber.

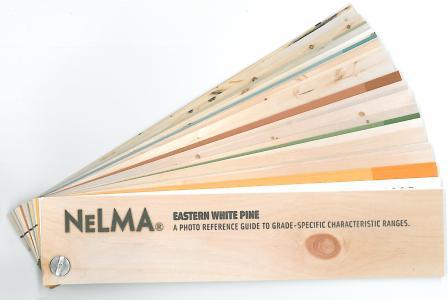

Part of NELMA since the merger with the Northern Softwood Lumber Bureau in 2017 and founded over 50 years ago, Biewer Lumber is a family-owned business with five state-or-the-art sawmills, including two in Michigan, two in Wisconsin and one down in Mississippi. With the capacity to produce more than 300 million board feet of dimensional lumber and timber annually, Biewer encourages environmentally responsible sustainable forestry practices and employee several foresters at each mill to manage its lumber procurement.

Here’s what they have to say about it, in their own words:

“It might be hard to imagine a lumber company claiming to be ‘green.’ But Biewer isn’t an ordinary lumber company. As a truly green company dedicated to sustainable practices for more than 20 years, we recognized early on that business and environmental stewardship can, and should, go hand-in-hand. We process over 1.8 million trees per year in order to meet the high demand for our lumber products. How can that be ‘green’? The answer is that we make it green—by responsibly managing the entire lumber process, from tree farming to processing, to ensure a sustainable future.”

“Our approach, which we call ‘From Forest to Framework™’ begins with the trees themselves. Biewer systematically selects the trees to be harvested, rather than clear-cutting. This process, called thinning, improves the growth rate, size and health of the remaining trees. Overcrowded trees are stressed trees, competing with each other for nutrients, water and sunlight. Thinned trees better withstand drought, insect infestation and extreme temperatures. This responsible harvesting allows the remaining trees to flourish.”

“Harvested trees arrive at one of Biewer’s state-of-the-art sawmills, where they are debarked. The bark is then either used as fuel for our on-site boilers, which supply heat to our kilns, or sold as landscape mulch. Each debarked log is scanned and an optimizing computer determines the best yield for each log. This efficient process results in very little waste or unsaleable boards.”

“All lumber processed in our sawmills is heat-treated to eliminate transferable fungus and pests, thus protecting living trees. After it is cut, each board is surfaced with a planer. All of our finished products are stamped with a heat-treated Association stamp. Processing lumber produces many by-products. Paper mills use the wood chips in the paper-making process, farmers use the shavings as animal bedding, and the sawdust is sold as wood flour or used on-site at Biewer as fuel to heat the boilers. Nothing is wasted.”

“Full-time foresters at each sawmill oversee the processes, ensuring our high standards are upheld while administering Biewer’s Private Landowner Assistance Program. Our logging crews are trained and follow Best Management Practices protecting out forests and insuring they are managed for sustainability. By maintaining healthy and thriving forests, minimizing or eliminating waste in our mills, and ensuring that every part of a harvested tree is used, Biewer is putting into practice our deep commitment to preserving and protecting the Midwest’s valuable forest resources.”

Check out Biewer’s offerings, including FSC-certified lumber, at BiewerLumber.com.