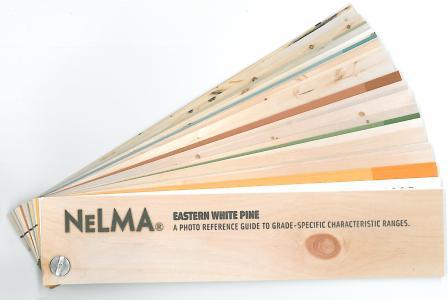

Slated to open in early 2018, the new $64.2 million, 92,500-square-foot building for the Bell Museum of Natural History on the University of Minnesota’s St. Paul campus is expected to become the largest commercial-scale use of thermally modified white pine in the country. Sourced locally in Minnesota, the Eastern White Pine was ‘cooked’ to remove the natural hemicellulose sugars, increasing the wood’s resistance to warping, weeping and decay.

About 40 percent of the museum’s exterior is covered in 21,000 square feet of this modified timber, chosen for its beauty, sustainability and local availability, according to the Star-Tribune. It also pays tribute to the history of Minnesota, where white pine is an iconic timber species. The wood comes from a forest located just thirty minutes away from the building site.

The process of ‘cooking’ wood originated in Finland, and has had limited use in the United States so far. It will be interesting to see whether this project inspires wider use of the technique, driving up demand for exterior applications of Eastern White Pine.

“The challenge has always been that you can’t use pine outdoors – that it has to be protected by the water,” says Dave Dimond, a principal at the architecture firm Perkins + Will, which designed the new museum. “This is a really new and exciting way to use white pine in a way that it’s never been used before.”

The building will include a 120-seat state-of-the-art digital theater functioning as the Twin Cities’ first public planetarium since the Minneapolis Public Library was demolished in 2002, and boasts a host of sustainable features, including solar panels, a pollinator garden, rain gardens and stormwater catchment.

“For the museum project, Arbor Wood selected Palisade, Minn.-based Superior Thermowood of Minnesota. About 8,000 board feet or enough wood to fill half a semitrailer truck was slowly heated in the kiln until it reached about 100 degrees Celsius. The heat cooks out the moisture and natural sugar that can cause wood to decay and attract insects. The heat is then spiked to 210 degrees Celsius so that the cellular makeup of the wood is changed, and it makes it less susceptible to water. The wood is cooled down with the addition of steam and is provided with some much-needed moisture so that the wood is not too brittle. The result is a wood that can withstand the elements without needing any other type of finishing. The entire process can take four to five days.

Several partners were needed to make the museum project work, including Cass Forest Products, the sawmill that harvested the pine, Woodline, the sawmill that prepared the thermally modified white pine for installation, and McGough, the construction company responsible for building the museum and installing the white pine.”

Images via the Star-Tribune