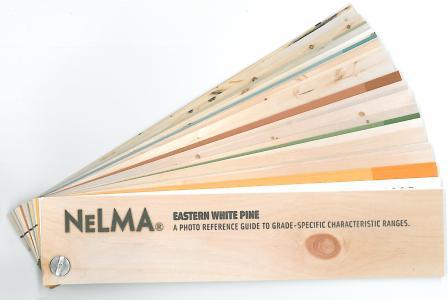

We’ve written many pages about the historical applications of Eastern White Pine, from the King’s Broad Arrow to some of the oldest colonial structures ever built on American soil. Rising high into the sky in majestic green groves, the trees proved to be of immense value to the first English settlers arriving in the Northeast, and they soon discovered that its light weight, rot resistance and easy-to-work characteristics lends itself to everything from kitchen utensils and cupboards to ship masts and the grandest of residential architecture.

Woodworkers still favor Eastern White Pine today for these very same qualities, using it to craft boats, birdhouses, millwork, mantels and much more. It’s highly stable when dry, surprisingly strong and durable for its weight. If you’re a professional or hobbyist woodworker, you could probably use some tips for using Eastern White Pine to its best advantages. Woodcraft Magazine offers some information in its Spotlight on White Pine.

Working white pine in the shop

Let your stock acclimate in your home or a temperature/humidity controlled shop for a few weeks to ensure stability later. Then keep the following points in mind.

- Rippling and routing. Eastern and western white pine contain far less pitch than other pines, but if you’re going to machine a lot of it, switch to a coated saw blade and router to avoid burning caused by gummy buildup. Clean the blade and/or cutters with a nylon bristle brush dipped in solvent.

- Assembly. Drill pilot holes for screws, especially in the much harder western white pine.

Deciding on the right finish

The small pin knots found in even the best grades of white pine will remain tight, yet they can bleed through a finish. To prevent this, seal them with shellac. Remember, white pine will gradually darken to pleasing yellow-orange color no matter what clear film finish you choose (it take all, except penetrating finishes, very well.) The preference is to leave the wood unstained. If you do decide to stain the wood, first put on a commercial conditioner or a wash coat of shellac (1 lb. cut) thinned with denatured alcohol to prevent blotching. Gel stain also works and won’t blotch, because it doesn’t penetrate.White pine finishing tips

Do not sand pine without a sanding block. The softness of the earlywood and the hardness of the lacewood result in ridges that won’t take stain or finish evenly.Tone the finish coat rather than stain. After finish-sanding, apply a thinned (50/50) coat of clear finish, such as polyurethane, and let dry. Sand lightly with 320-grit, remove dust, and then brush on a clear finish toned to the desired color with a Mixol tint (available at Woodcraft) and let dry. Repeat for a darker color.

Check out lots more valuable woodworking information at the Woodcraft Magazine website.