The international Mass Timber Conference brought global experts in the mass timber industry together in Portland, Oregon this week to discuss how we can increase the use of wood in mid-rise and tall buildings around the world. The conference explored the entire supply chain for innovative wood technologies like cross-laminated timber and laminated veneer lumber. One of the main speakers, Jason Metric of the Sustainable Forestry Initiative (SFI), spoke about four ways responsible forestry supports wood construction.

The speech focused on how forest certification can open up global markets in green building, a highly relevant topic for anyone working in the forestry industry today. For anyone who couldn’t be present at the event, SFI has outlined the four ways in a post on Treehugger.com.

The 4 ways in-depth:

1. Ensure the wood products in your construction project – whether small buildings or tall buildings – come from certified, responsible, and legal sources.

Watch architect Michael Green talk about the future of wooden skyscrapers and the importance of sustainable building materials here:2. In North America, more than 285 million acres/115 million hectares of forests are certified to the Sustainable Forestry Initiative Forest Management Standard and millions more are positively impacted by SFI Fiber Sourcing Standard.

There’s a simple way you can ensure that our forests remain healthy. Look for the SFI® label on any wood, paper and packaging product you purchase. It’s your assurance that what you buy comes from responsibly managed and legal forests.

3. SFI is recognized by LEED and other top green building rating systems.

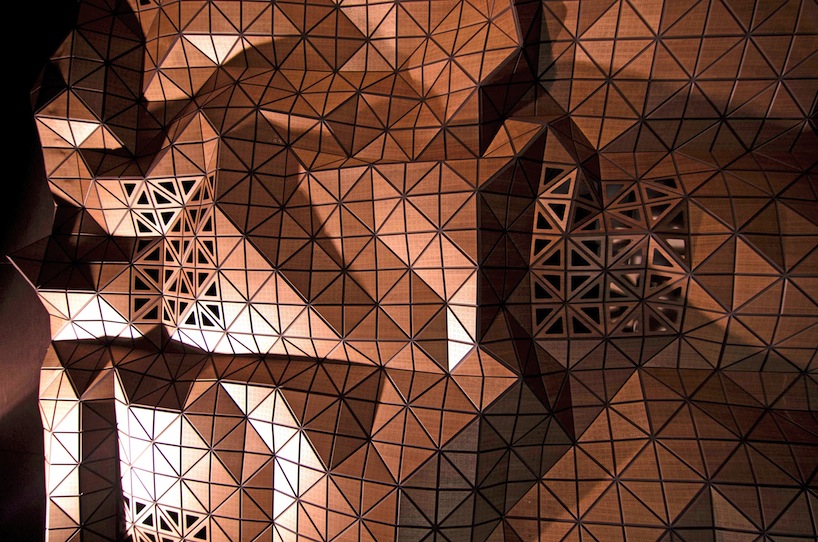

On April 5, 2016, the U.S. Green Building Council (USGBC) issued a LEED alternative compliance path (ACP) that recognizes wood and paper from the SFI Program as part of an integrated approach to encouraging environmentally responsible forest management and eliminating illegal wood from the building material’s supply chain.4. Wood is celebrated by leading architects for its beauty, versatility, and renewability.

The 2017 SFI Certified Wood Award, part of the North American Wood Design and Building Awards program, was presented to Hacker, Portland-based architects. The Black Butte Ranch used Sierra Pacific windows and other wood certified to the SFI Standard.