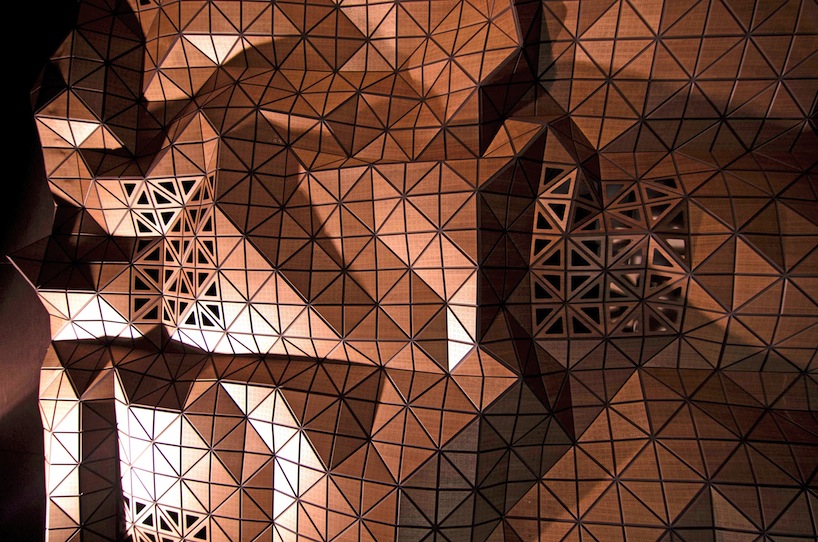

In forests that aren’t actively managed, dry pine needles can accumulate to the point of becoming a wildfire hazard. But there are all kinds of uses for this biodegradable material, from mulch to livestock bedding, and one designer has even found a way to turn them into stylish home accessories. Guarav MK Wali’s “Cheer Project” separates the fiber of the pine needles and binds them with resin, waxes and natural dyes to produce a 100% bio-based material that can be molded into items like cups and trays.

“It has been an experiment to understand the root of a local material and its potential and possibilities in an ever-increasing demand for alternatives for the production of sustainable objects,” says the designer. “The ultimate concept rested on the fusion of local craftsmanship and sustainable utilization of a naturally abundant novel material; the rediscovery of the pine needle.”

Wali came up with the idea after frequent forest fires caused serious damage to the northern region one India, which is home to an abundance of pine trees. His zero-waste process uses a shredder built with open-source plans by Precious Plastic and can be mimicked by just about anyone who wants to try it for themselves. The designer now holds artisan training workshops for women to teach them how to make objects with the material, generating new household income.

“It seeks to reinvent the way we perceive pine needles to provide a solution for these complex and interrelated problems. A new way of thinking that tackles the plurality of the situation with a holistic approach. A system of production processes, products and sustainable functioning that gives momentum to pine needle as a revolution that empowers the local communities and provides them with economic sustenance, while providing an alternative to plastic in these environmentally tragic times.”

“The principles upon which the model works was not the confrontation of humans and nature, but their assimilation. Where human progress is enhanced by nature, kindling a symbiotic relationship between humans and nature that we seem to have forgotten with time.”